|

|

|

Monday 21st July 2014

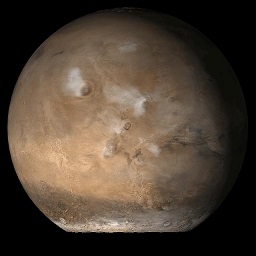

Machined in Birmingham – Headed for Mars

|

High-precision components machined by GB Precision, will be making the journey into space on the mission planned to be heading to Mars in 2016.

The spacecraft will be carrying instruments to detect trace atmospheric gases, many of which are important markers of geophysical and/or biogenic activity – it is into these instruments that the components machined by GB Precision will be integrated.

The ten components were machined from RSA – a very pure, and therefore costly, form of aluminium. In terms of size, the largest component would fit into a 90mm cube, the smallest into a 30mm cube.

Each component incorporates almost 100 different individual features, including cut-outs and reliefs, with a minimum of four datum points on different faces, and a required machining tolerance of between 3 – 20 microns. To achieve this level of accuracy, GB Precision carried out the great majority of the work on its state-of-the-art Roders CNC multi-axis milling machine.

Even with this advanced technology, two or three different set-up operations for each component were required and bespoke fixturing had to be developed to cope with the different geometries and datum positions.

Director Paul Turner sums up, “We tackle some pretty tricky machining projects for customers from F1 to pharmaceutical, that’s our speciality – but this job certainly extended our capabilities. We are very proud that due to our expertise, components machined here in Birmingham will help discover if life ever existed on Mars.”

|

|

|